Your Guide to an AC to DC Battery Charger

An AC to DC battery charger is one of those essential bits of kit we rarely think about. In simple terms, it takes the alternating current (AC) from a standard wall socket and converts it into the direct current (DC) that your batteries need to charge. This step is non-negotiable because while our national grid sends out power as AC, all batteries store and deliver it as DC.

Without this clever conversion, everything from your smartphone to an electric car would be useless once its first charge ran out.

The Unsung Hero of Our Modern World

Ever stopped to think about the quiet magic happening every time you plug something in? The electricity flowing from your wall is fundamentally different from the energy your device's battery can actually use. This mismatch is solved by one of the most common yet overlooked devices in our lives: the AC to DC battery charger.

Think of it like a currency exchange. The power grid operates in the ‘currency’ of Alternating Current (AC) which is brilliant for travelling long distances. But your phone, laptop or electric vehicle battery only ‘accepts’ Direct Current (DC). The charger is the indispensable bureau de change, swapping one form of energy into the other safely and efficiently.

Why This Conversion is So Critical

This process is not just a technical detail; it's the very foundation of our portable, electronic world. Without it, every battery-powered gadget would be a single-use item. This simple principle scales up from the smallest devices to the largest electric vehicles creating a massive demand for reliable charging solutions. For those interested in diverse energy solutions, it's also worth Exploring solar energy options.

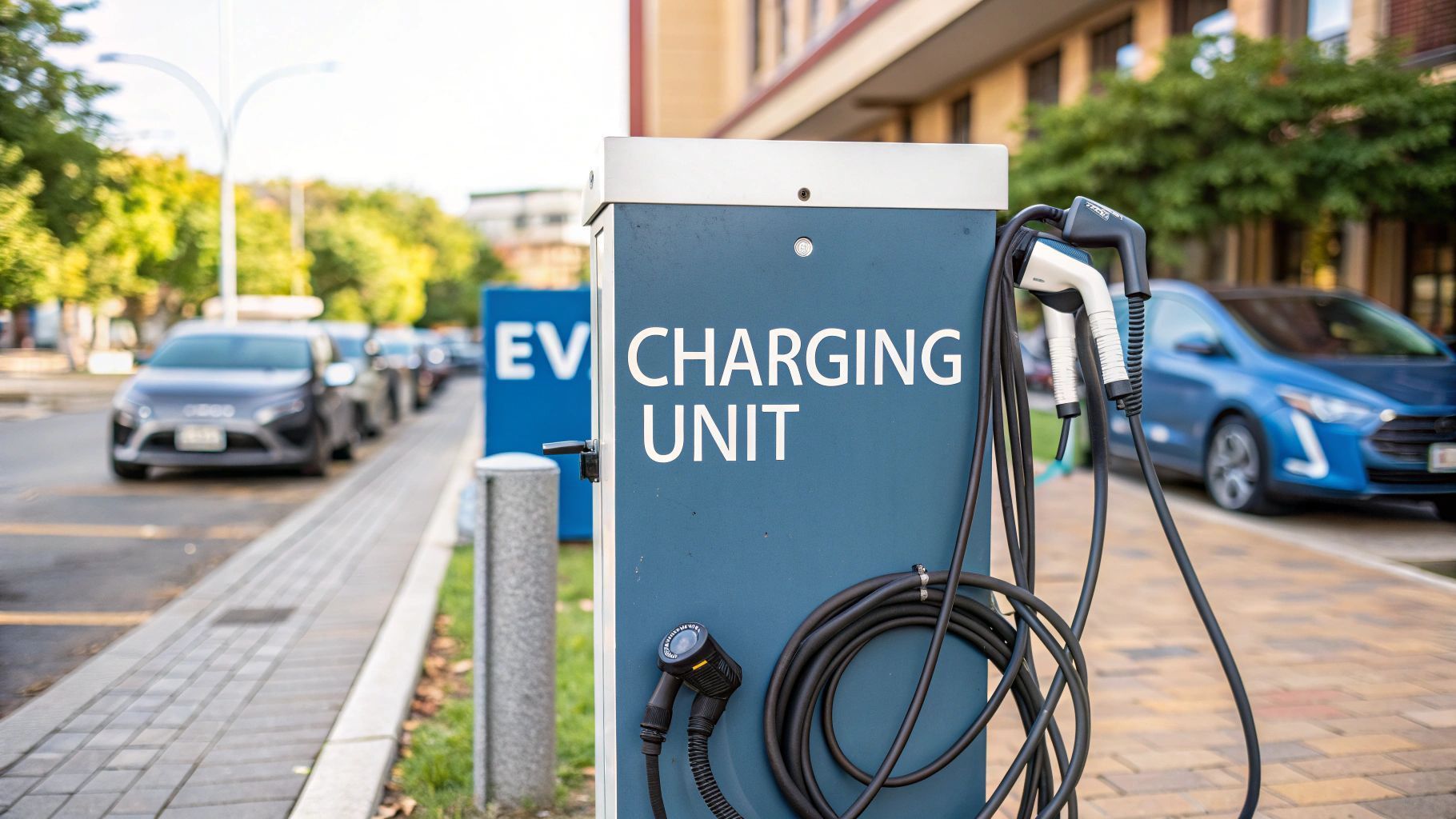

The explosion in EV ownership in the UK really brings this dependency into focus. Right now, about 28% of new vehicle sales in the UK are either fully electric or plug-in hybrids, which is creating an urgent need for robust charging infrastructure. This trend is set to push the UK's electric vehicle charging equipment market to 64.36 thousand units by 2025 , highlighting just how vital the humble AC to DC charger is to a greener future. You can discover more insights about the UK's EV charging index on rolandberger.com.

The Rise of Mobile Charging: A Lucrative Opportunity

This reliance on charging has also opened up a huge business opportunity, especially for mobile charging services. A van kitted out with a powerful, portable charger can become a roadside hero for stranded EV drivers or a vital service for commercial fleets. This service is a game-changer because it brings the solution directly to the problem, offering unparalleled convenience.

By offering on-demand charging an operator directly tackles 'range anxiety'—the number one fear for many EV drivers. This service fills a critical gap in the market, turning a common problem into a profitable business with significant earning potential.

The financial upside is compelling. A mobile charging operator could set a call-out fee and then charge a premium per kilowatt-hour delivered. Completing just a handful of service calls a day could generate a substantial income, turning an essential piece of technology into a lucrative venture.

How AC to DC Power Conversion Really Works

To get your head around the magic inside every ac to dc battery charger , you first need to understand the two different types of electrical current. Think of Alternating Current (AC) – the power coming out of your wall socket – as a saw blade moving rapidly back and forth. It’s brilliant for travelling long distances across the national grid but its constantly reversing direction is completely useless for charging a battery.

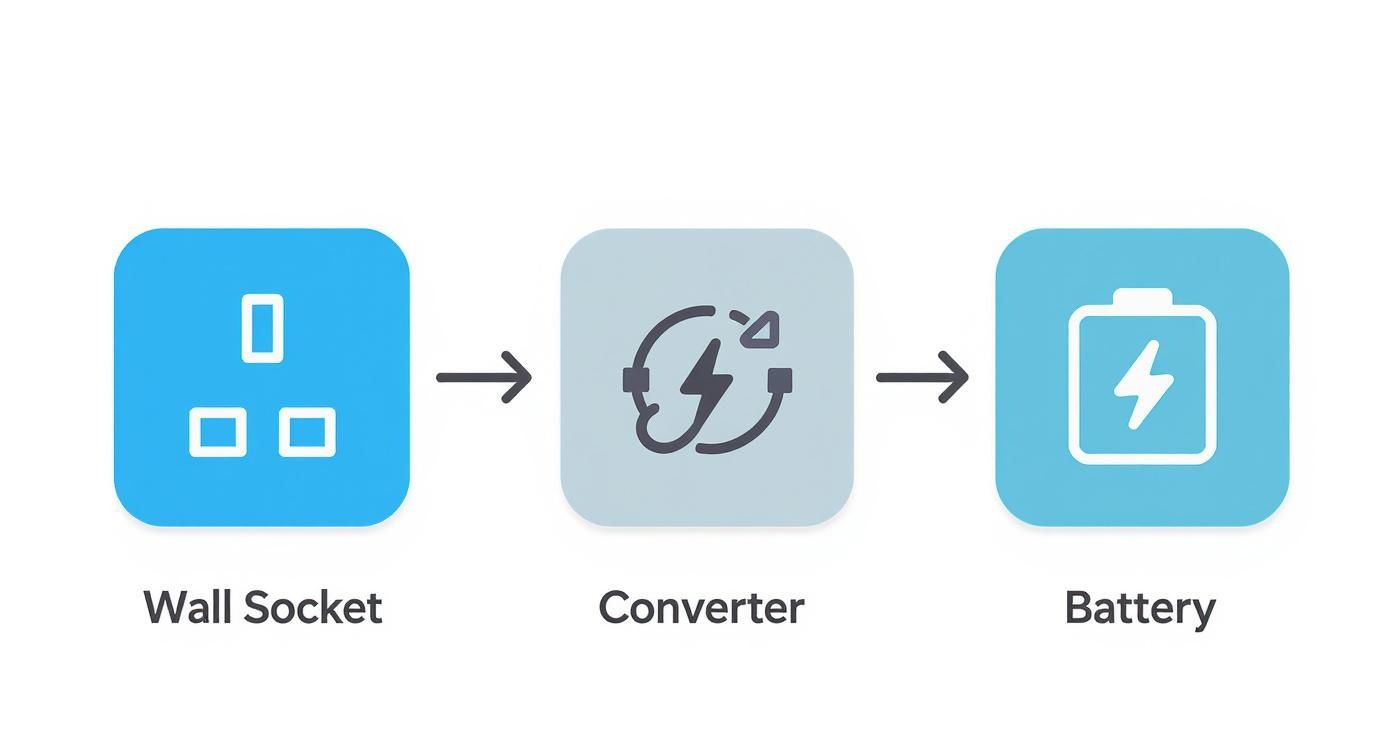

Direct Current (DC), on the other hand, is like a steady, one-way river. This is the only kind of power that batteries can actually store. The charger's main job, then, is to act as a clever converter, turning the chaotic push-pull of AC into the smooth, directional flow of DC that your devices need to come alive.

This infographic breaks down that simple but essential journey from the wall socket to your battery.

As you can see, the charger is the critical middleman, taming raw grid power into something stable and usable for your battery.

The Four Key Stages of Conversion

This transformation from AC to DC doesn’t just happen in one go. It’s actually a carefully orchestrated four-part process happening inside the charger. Each stage is handled by a specific component and they all have to work in perfect harmony to deliver a clean, stable supply of power.

-

Transformation : First up, a transformer takes the high voltage from the mains (usually 230V in the UK) and steps it down to a much lower, safer level that’s suitable for the battery. It’s a bit like a gearbox, reducing speed to gain more precise control.

-

Rectification : Next, a component called a rectifier – often a bridge of diodes – forces the alternating current to flow in a single direction. It essentially flips the negative, backward-flowing parts of the current, turning the choppy AC wave into a bumpy but purely positive DC signal.

-

Filtering : The raw DC coming from the rectifier is still far too rough for a battery. A filter , which is usually made of capacitors, comes in to smooth out all those bumps and ripples. Think of it like the suspension on a car, turning a rough, jarring ride into a smooth journey.

-

Regulation : Finally, a regulator circuit makes sure the output voltage is perfectly constant. It acts like a gatekeeper, stopping any fluctuations and delivering the precise voltage the battery needs for a safe and efficient charge.

Together, these four components are the heart of any AC to DC battery charger. From the tiniest phone plug to a massive EV unit, this fundamental process ensures the wild energy from the grid is tamed into the stable, life-giving power your batteries depend on.

Understanding Power and Cost

The amount of power a charger can deliver is measured in watts (W), which you get by multiplying its voltage (V) by its current (A). So, a 12V charger that delivers 5A is providing 60W of power. This number is what determines how quickly it can charge a battery, a process measured in kilowatt-hours (kWh).

Getting a grip on this relationship is vital, especially for mobile charging operators who need to keep a close eye on their costs. If you want to dig into the numbers, our guide explains how to calculate a kilowatt-hour and what it really means for your energy bills and profit margins. This knowledge allows an operator to work out the exact cost of recharging their mobile unit versus the revenue they can earn from each customer.

From Theory to Practical Application

While the inner workings might sound a bit technical, the result is simple: a reliable source of DC power. This process is universal, whether we’re talking about a small USB charger in your pocket or a high-powered system used for mobile EV charging.

To make it even clearer, here’s a quick breakdown of what each core component does, along with a simple analogy to help it stick.

Key Components Inside an AC to DC Charger

| Component | Primary Function | Simple Analogy |

|---|---|---|

| Transformer | Reduces the high AC voltage from the mains to a lower, usable level. | A gearbox that reduces high engine speed to a manageable wheel speed. |

| Rectifier | Converts the back-and-forth flow of AC into a one-way flow of DC. | A one-way valve in a pipe that only allows water to flow in a single direction. |

| Filter | Smooths out the pulsations and ripples in the raw DC output. | A reservoir that evens out the flow of a river, turning surges into a steady stream. |

| Regulator | Ensures the final DC output voltage is constant and stable. | A cruise control system that maintains a car's exact speed, regardless of hills. |

By mastering these concepts, you gain a much deeper appreciation for the technology tucked away inside every ac to dc battery charger . This isn’t just academic knowledge; it's the foundation for making smart decisions about charging equipment, whether it’s for your own use or for building a successful mobile charging business.

Exploring the Different Types of Chargers

Not all chargers are created equal and understanding the differences is key to making the right choice. The world of an AC to DC battery charger is diverse, with each type designed for a specific job, from reviving a small gadget to powering an entire electric vehicle. At their core, chargers are distinguished by their internal technology.

Older, simpler designs often rely on linear power supplies . These are rugged and produce a very clean DC output but they’re also heavy, bulky and terribly inefficient, wasting a lot of energy as heat. By contrast, nearly all modern electronics use Switched-Mode Power Supply (SMPS) chargers.

These are the lightweight, compact chargers we’re all familiar with. SMPS technology is far more efficient at converting AC to DC with minimal energy loss, making it perfect for everything from laptops to high-powered EV charging systems.

From Trickle to Smart Charging

Beyond the internal gubbins, chargers are also categorised by how smart they are. The technology they use determines how they interact with a battery, which directly impacts charging speed, battery lifespan and overall safety.

- Trickle Chargers : These are the most basic type, feeding a slow, constant current to a battery. They are best for maintaining a full charge on batteries stored for long periods, like those in classic cars or boats, stopping them from self-discharging.

- Fast Chargers : Built for speed, these chargers pump out a much higher current to slash charging times. While convenient, using them frequently can generate more heat and potentially shorten a battery’s lifespan over the long run. They’re best used when a quick top-up is essential.

- Smart Chargers : This is where modern charging technology really shines. A smart charger talks to the battery’s management system (BMS) to monitor voltage, temperature and charge level. It then adjusts the current in stages to charge as fast as possible while protecting the battery's health, stopping automatically when it's full to prevent overcharging.

Smart charging is now the industry standard for high-value assets like electric vehicles. This intelligent approach not only ensures safety but also plays a huge part in extending the lifespan of expensive battery packs, which can last for 15-20 years with proper care.

The Crucial Difference in EV Charging

Nowhere are these distinctions more important than in the world of electric vehicles. When people talk about AC and DC EV chargers, they're not referring to the power coming from the grid but rather where the final conversion to DC happens. This difference is critical for understanding charging speeds.

An Onboard AC Charger is the unit built into the electric vehicle itself. When you plug your car into a standard home or public AC charging point, you’re just supplying AC power to this onboard unit. It’s the car that does the hard work of converting AC to DC before sending the power to the battery.

These onboard chargers are limited in size and power to keep the vehicle’s weight down, typically ranging from 3.6kW to 22kW . This makes them perfect for overnight charging at home or topping up at the office but they're not quick enough for long journeys.

Unlocking Speed with Off-Board DC Chargers

In contrast, an Off-Board DC Charger —often called a DC Fast Charger (DCFC) or a Level 3 charger—is a much larger, more powerful unit that isn't part of the vehicle. This external charger converts AC grid power to DC before it even gets to the car.

Because the conversion happens outside the vehicle, these chargers can be much bigger and more powerful, delivering anywhere from 50kW to over 350kW of DC power directly to the battery. This bypasses the car's smaller onboard charger entirely, allowing for incredibly fast charging times. We're talking hundreds of miles of range in under 30 minutes.

This incredible speed makes DC chargers essential for public charging networks and motorway service stations, making long-distance EV travel a reality. It's also the technology that powers mobile charging solutions, where a powerful off-board charger can be brought directly to a stranded vehicle.

The UK's charging infrastructure currently leans heavily on AC chargers, which make up around 80.5% of the market thanks to their lower cost and suitability for home installation. However, the push for faster, more convenient public charging is driving huge investment in DC infrastructure to tackle range anxiety. You can read the full research on the UK's EV charging market at imarcgroup.com.

For those looking to charge a conventional vehicle, selecting the right device is paramount. You might be interested in our guide on choosing the best battery charger for a car , which covers the key features to look for with lead-acid batteries.

The Mobile EV Charging Business Opportunity

The explosion of electric vehicles on UK roads has opened up a fascinating gap in the market. While fixed charging stations are popping up more frequently, they can't be everywhere. This creates a brilliant opportunity for a 'charging station on wheels'—a business built around a powerful mobile ac to dc battery charger system.

This kind of service directly tackles 'range anxiety', the number one fear holding many people back from switching to electric. By kitting out a van with a hefty battery bank and an off-board DC fast charger, you can deliver on-demand power to stranded drivers, top up commercial fleets in remote spots or even offer charging at events where there's no fixed infrastructure. The primary advantage is offering a premium, convenient service that customers are willing to pay for.

The Business Model and Its Profitability

The idea is simple but incredibly powerful. You invest in a good van, a high-capacity battery system and a portable DC fast charger. This setup turns your vehicle into a mobile power source that can deliver a significant charge—often 20-30 kWh —to a stranded EV in a short amount of time. That's more than enough juice to get a driver to their destination or the nearest permanent charging point.

Making money is straightforward. Most operators use a two-part pricing model: a fixed call-out fee, much like traditional roadside assistance, plus a per-kilowatt-hour (kWh) charge for the energy you provide. This structure ensures every job is profitable and the potential earnings are substantial.

And it’s not just for emergencies. You can also cater to commercial fleets that don’t have enough chargers at their depot or whose vehicles run routes with few public charging options. Offering scheduled top-ups can build a reliable, recurring revenue stream for your business.

Calculating Your Startup Costs

Getting a mobile EV charging business off the ground requires a serious initial investment but the potential returns make it a compelling prospect. Your main costs fall into three buckets.

- The Vehicle : You'll need a dependable van with a decent payload, like a Ford Transit or Mercedes Sprinter. It has to be sturdy enough to safely carry the heavy battery bank and all the charging gear.

- The Charging System : This is the heart of your operation and where the biggest chunk of your budget will go. It includes a substantial lithium-ion battery bank (think 50kWh or more) and a portable DC fast charger. Crucially, this must be an off-board unit to pump power directly and quickly into the EV's battery.

- Ancillary Equipment and Overheads : This covers everything else—safety gear, insurance, branding for your van and a booking and payment system. You’ll also need to budget for some initial marketing to get your name out there.

You're realistically looking at a startup budget of anywhere from £50,000 to £80,000 for a professional, reliable setup. While that’s a big number, there are plenty of financing and leasing options available to make that initial outlay more manageable.

Projecting Your Potential Earnings

The profitability of this business comes down to your pricing and how many calls you can handle each day. Let's walk through a realistic scenario to see what’s possible for a sole operator.

Imagine you set a £40 call-out fee and charge 70p per kWh delivered. A typical job might be giving a stranded driver a 20kWh top-up.

- Revenue per call : £40 (call-out fee) + (20 kWh x £0.70/kWh) = £40 + £14 = £54

That single call brings in £54. Meanwhile, your costs are surprisingly low. Your main expense is the electricity to recharge your van's battery bank. If you do this overnight on an off-peak tariff at around 15p per kWh , the cost for that same 20kWh delivery is just £3.00 .

Even after factoring in fuel for the van and other daily overheads, the profit margin on each call is fantastic. An operator completing just three or four of these calls a day can earn a very healthy income.

A Look at Annual Profitability

To get a clearer picture of the long-term financial sense, let's project the potential earnings over a year. The table below shows what's possible based on a modest number of daily service calls, working five days a week for 48 weeks of the year.

Projected Annual Earnings for a Mobile EV Charger Operator

This table provides an example of potential revenue and profit for a mobile EV charging business, based on different daily service call scenarios.

| Service Calls Per Day | Average Revenue Per Call | Projected Annual Gross Revenue | Estimated Annual Profit |

|---|---|---|---|

| 2 | £54 | £25,920 | £16,500 |

| 3 | £54 | £38,880 | £26,500 |

| 4 | £54 | £51,840 | £36,500 |

| 5 | £54 | £64,800 | £46,000 |

Note: Estimated Annual Profit accounts for electricity costs, vehicle running costs, insurance and other typical business overheads.

As you can see, even a conservative three service calls a day could generate an annual profit of over £26,000 . An ambitious operator who lands contracts with local businesses or fleet operators could easily push past five calls a day, driving their earnings much higher. This business model, powered by a mobile ac to dc battery charger , offers a genuinely practical and profitable way to solve one of the biggest challenges in the transition to EVs.

How to Choose the Right AC to DC Charger

Picking the right AC to DC battery charger is one of the most important decisions you’ll make, whether you're powering a small gadget or a sophisticated mobile EV charging system. The right choice doesn't just guarantee efficient performance; it's also about protecting the safety and lifespan of your valuable batteries. Getting this right starts with understanding a few core specifications.

Think of these specifications as the charger's DNA. They spell out exactly what it can do and which devices it can safely power up. Getting them right is non-negotiable if you want to avoid damaging your equipment.

Understanding Core Charger Specifications

The three most critical numbers on any charger are its output voltage, current and power. These figures work together to define its performance and, crucially, its compatibility with your batteries.

- Output Voltage (V): This is the absolute deal-breaker. The charger's voltage must match the battery's required voltage precisely. Getting this wrong can cause irreversible damage almost instantly.

- Current Rating (Amps or A): This number dictates how fast the battery will charge. The charger's current rating should be at least equal to what the device needs. A higher amp rating is perfectly safe, as the device will only draw the current it needs and no more.

- Power (Watts or W): This is the total energy output, a simple product of volts multiplied by amps (V x A = W). For instance, a 12V charger that delivers 10A is providing 120W of power.

When you're choosing a charger, the golden rule is simple: match the voltage exactly and make sure the current is equal to or greater than what your device requires. This one check is your best defence against equipment failure.

Matching the Charger to the Battery Chemistry

Beyond the raw numbers, you have to consider the battery's specific chemistry. Different types of batteries have very different charging needs and using a one-size-fits-all charger can be inefficient at best and dangerous at worst.

For example, the Lithium-ion (Li-ion) batteries found in almost all modern electronics and EVs need a sophisticated, multi-stage charging process to keep them healthy and extend their lifespan. By contrast, traditional Lead-Acid batteries, still common in many vehicles, follow a completely different set of charging rules.

Using a charger designed specifically for your battery’s chemistry is vital. A proper smart charger will automatically adjust its output based on the battery's state, preventing overcharging and significantly extending its overall service life.

Prioritising Safety and Build Quality

A charger is only as good as its build quality and safety features. Here in the UK, always look for essential safety certifications like the UKCA and CE markings . These stamps of approval mean the charger meets strict safety, health and environmental standards. Never be tempted by uncertified chargers—they pose a serious risk of fire or electric shock.

Efficiency is another key factor. A charger's efficiency rating tells you how much of the AC power it pulls from the wall socket is actually converted into DC power for your battery. A higher efficiency rating (think 95% or more ) means less energy is wasted as heat. That not only saves you money on your electricity bill but also helps the charger run cooler and last longer.

Finally, just look at the build quality. Does it have a robust casing? Are the connectors high-quality? Is there an effective cooling system, especially on high-power units? For something like a mobile EV charging business where the kit is used daily, investing in a durable, well-built AC to DC battery charger is absolutely essential for reliability and long-term profit.

Got Questions About AC to DC Chargers? We’ve Got Answers.

When you’re dealing with anything from personal electronics to a full-scale mobile EV charging business, it’s natural for a few questions to pop up about the ac to dc battery charger . Let’s clear up some of the most common ones.

Getting these details right gives you the confidence to use your gear safely and get the best possible performance and lifespan out of your batteries.

Can I Use Just Any Charger for My Device?

Absolutely not. This is a common and dangerous mistake. You must always match the charger's output voltage (V) to what your device requires. Using the wrong voltage can fry your electronics in an instant.

Polarity is just as important—look for the small diagram on the device and charger to make sure they match. As for the current rating (Amps), the charger needs to provide at least what the device needs. Using a charger with a higher amp rating is perfectly fine, as the device will only draw the current it requires. Always double-check your device’s label for the correct specs before plugging anything in.

What's the Big Deal with a ‘Smart Charger’?

The difference between a basic charger and a smart one is all in the brains. A standard charger just pushes out a constant current, which is a bit like leaving a tap running. If you leave it connected too long, it will overcharge the battery, causing damage and shortening its life.

A ‘smart’ charger, on the other hand, is in constant communication with the battery. It uses a multi-stage charging process, checking the battery's status and adjusting the charge as it goes. Crucially, it stops automatically when the battery is full. This not only speeds things up but also massively extends battery life and improves safety.

If you want to get deeper into the lingo, our comprehensive EV charging glossary is a great place to start.

How Do I Figure Out My Profit from Mobile EV Charging?

Let’s break it down. First, calculate your total revenue from a single job. This will be your service fee (say, a £40 call-out charge ) plus what you earn per kWh sold (for example, 70p/kWh ). So, a simple 20kWh top-up could bring in £54.

Next, subtract your costs. This includes the electricity to recharge your mobile unit (which you’ll want to do at a cheap off-peak rate of around 15p/kWh ) plus your vehicle running costs and equipment depreciation.

If you manage just three calls a day, your daily revenue could hit £162. With daily costs around £35, you're looking at a daily profit of £127. That adds up to a potential annual profit of over £30,000 working just five days a week.

This simple calculation shows the strong financial case for a mobile charging service. The high-value convenience you offer allows for healthy profit margins, even after accounting for all operational costs.

Is Faster Charging Always a Good Thing?

Not always. While it’s incredibly convenient, constantly hitting a battery with very fast charging generates a lot of extra heat and puts its internal components under stress. Over time, this can wear down the battery's capacity and shorten its overall lifespan.

For day-to-day use, especially when charging overnight, sticking to a standard or slower charger is much healthier for the battery in the long run. It's best to save the rapid charging for when you genuinely need it—like on a long trip or during an emergency call-out.

Are you looking to launch your own mobile charging service or need a reliable solution for your EV fleet? ZAPME offers pioneering mobile EV charging units designed and built in the UK. Discover our range of powerful, portable charging systems and revolutionise how you power your vehicles by visiting https://www.zapme.biz.