Your Guide to a Battery Charger AC to DC

At its core, a battery charger ac to dc is the crucial middleman between the power in your wall and the battery in your device. It takes the Alternating Current (AC) from a standard socket and converts it into the Direct Current (DC) that batteries need to store energy.

Without this conversion, charging almost any modern gadget—from your phone to an electric car—would be impossible. It’s a fundamental process that makes our portable, electric world tick.

Why AC Power Needs Converting for Your Battery

Ever wondered why you cannot just plug a battery straight into the mains? It all comes down to the two different flavours of electricity involved. The national grid supplies Alternating Current (AC) because it’s incredibly efficient for sending power over long distances but the catch is that its current constantly flips direction.

Batteries, on the other hand, only work with a steady, one-way flow of energy called Direct Current (DC) . Think of AC as a busy two-way street with traffic zipping back and forth, while DC is a simple one-way road. The AC to DC charger acts as a traffic controller, funnelling all that chaotic energy into a single, orderly lane to safely fill up the battery.

The Foundation of Modern Charging

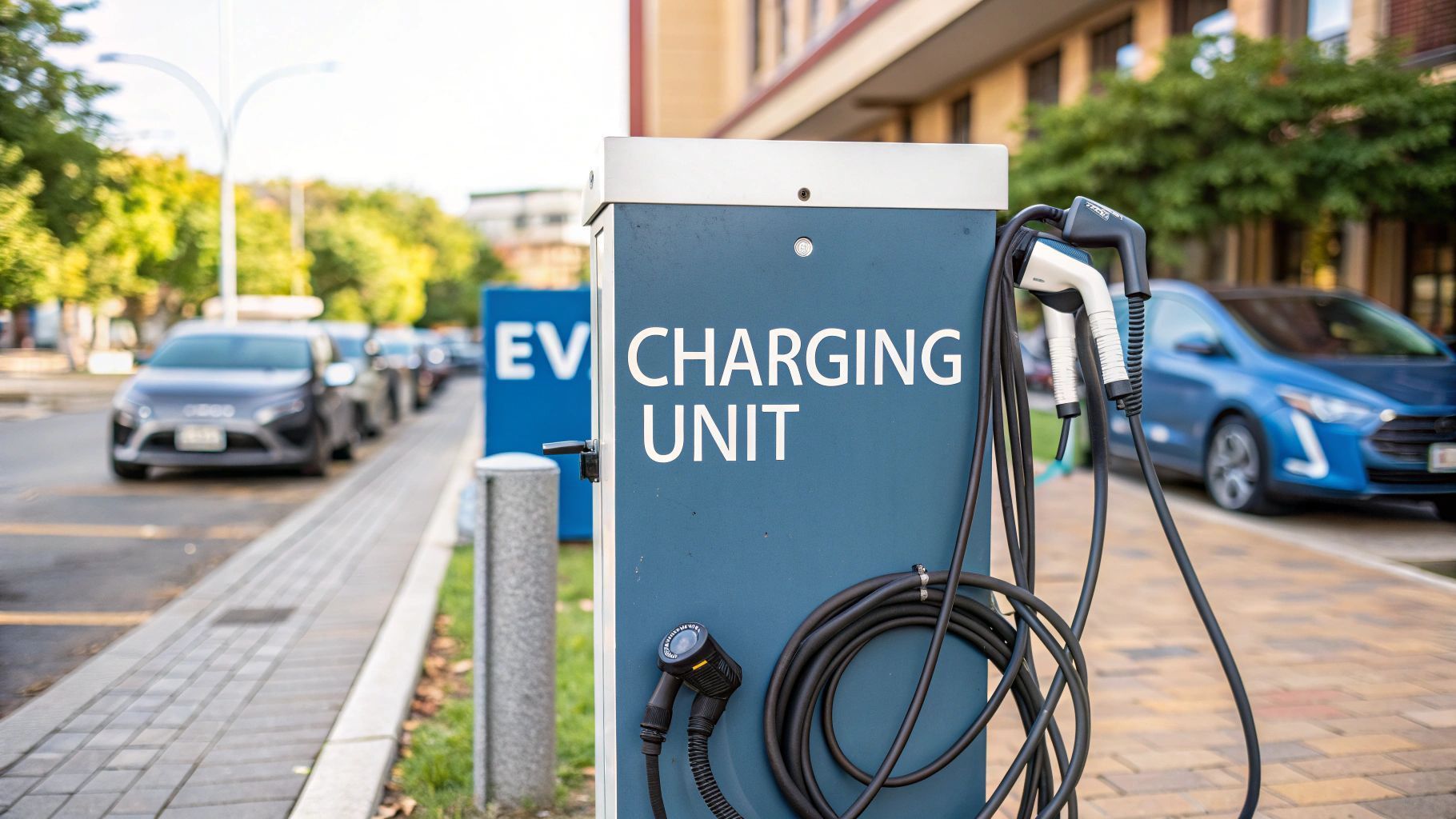

This conversion is not just a technical detail; it is the bedrock of modern life. Every single time you plug something in to charge, an AC to DC converter is quietly managing that energy transfer. It is the technology that made portable power a reality and now it is spearheading the electric vehicle revolution across the UK.

As more drivers make the switch to electric cars, the demand for reliable, accessible charging has skyrocketed. This opens up a massive commercial opportunity, especially for mobile charging operators who can bring this vital service directly to customers wherever they are.

A mobile charging service has some clear advantages:

- Flexibility: You can set up anywhere, from a city centre car park to a remote festival, meeting demand right where it happens.

- Lower Overheads: A mobile unit sidesteps the hefty costs of installing and maintaining fixed charging stations.

- Premium Service: On-demand charging, especially for roadside assistance, is a convenient service that customers are willing to pay a premium for.

The core idea is simple but powerful. By converting mains AC into battery-friendly DC, a mobile operator can effectively turn grid electricity into a profitable, on-the-go service for a growing market of EV drivers.

Getting your head around this basic technology is the first step to capitalising on this expanding market. The income potential is substantial—a mobile charging operator offering roadside assistance can realistically earn between £120 and £260 per day from just a handful of call-outs. This business model turns a technical necessity into a genuinely lucrative venture, bridging the gap between the national grid and the modern driver.

How Electricity Is Converted from AC to DC

The journey electricity takes from a wall socket to your battery is not as simple as just plugging it in. A battery charger ac to dc is a sophisticated bit of kit that has to completely transform the power before it is safe to use. Think of it like trying to fill a water bottle from a fire hose that blasts water on and off unpredictably. The charger’s job is to tame that chaotic flow into a steady, usable stream.

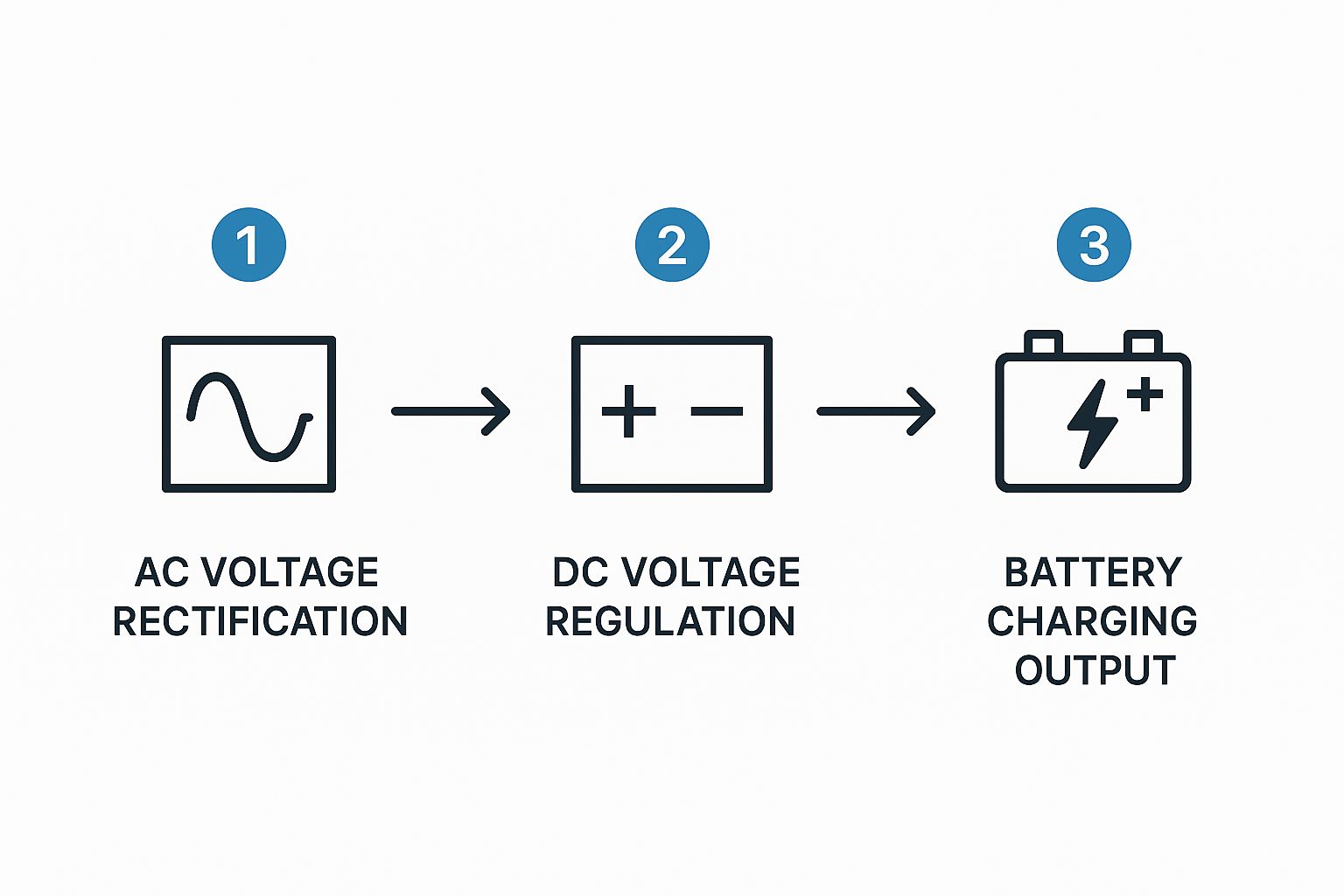

This conversion happens in a few crucial stages. Each step is designed to take high-voltage, alternating current and make it stable, safe and suitable for charging. Without this careful sequence, the delicate chemistry inside a battery would be quickly and irreversibly damaged.

This infographic breaks down the three key stages of AC to DC conversion, showing the flow from raw mains power to the final, clean charging output.

As you can see, the process is a funnel. It progressively refines the electricity until it is perfectly controlled and ready for your battery.

The First Step: Transformation and Rectification

The process kicks off with a transformer , which you can think of as a gearbox for electricity. Mains power in the UK comes in at around 230 volts but most batteries need a much lower voltage to charge safely. The transformer’s first job is to step this high voltage down to a more manageable level.

Once the voltage is right, the power moves to a rectifier . This is where the magic of AC to DC conversion really begins. A rectifier acts like a one-way valve or a turnstile for electricity, forcing the current to flow in only one direction and blocking it when it tries to reverse.

This stops the current from alternating back and forth, turning it into a bumpy, pulsating stream of DC. It is a crucial first step but the power is still far too choppy for a battery to handle.

The Second Step: Smoothing Out the Pulses

After rectification, the electricity is technically DC but its flow is incredibly rough. Sending this pulsating current straight to a battery would be inefficient and could even cause damage. This is where the smoothing stage comes in.

This is usually done with capacitors , which act like small, temporary reservoirs for electrical energy. As the pulses of DC arrive, the capacitors charge up on the peaks and then release that stored energy during the dips.

This action fills in the gaps, transforming the bumpy electrical flow into a much steadier, more consistent stream. It is a bit like turning a series of short bursts from a hosepipe into a continuous, even flow of water.

The Final Step: Regulation for a Perfect Output

Even after smoothing, the DC voltage can still have tiny fluctuations that might impact charging performance and long-term battery health. The final stage, regulation , is the quality control check that ensures a perfectly stable output.

A regulator circuit constantly monitors the output voltage. It makes tiny, real-time adjustments to keep it precisely at the required level, no matter what is happening with the input power or the demands of the battery.

This level of precision is vital for modern batteries, especially the lithium-ion cells you find in electric vehicles.

A stable and accurate voltage ensures the battery charges efficiently, maximises its lifespan and prevents overcharging, which can be dangerous. It's the final polish that makes the charger safe and effective.

Understanding these mechanics is key, especially when it comes to boosting EV charging efficiency . This complete, multi-stage process is what makes every battery charger ac to dc a clever piece of technology, ensuring power is delivered just right, every time.

Comparing Different Types of AC to DC Chargers

Not all battery charger ac to dc units are created equal. Getting your head around the key differences is vital for picking the right tool for the job, whether you are topping up a small power bank or launching a mobile EV charging business. The technology packed inside these devices has a massive impact on their efficiency, size and cost.

Broadly speaking, the charger world is split into a few camps. You have got the old-school linear chargers—simple and reliable. Then there are the modern switching-mode power supplies (SMPS), which are popular for their compact size and high efficiency. Finally, smart chargers throw advanced tech into the mix, fine-tuning the whole process for safety and battery health.

Traditional Linear Chargers

Linear chargers are the old guard. Their design is beautifully straightforward, using a transformer to step down the voltage and a basic circuit to regulate the output. This simplicity makes them cheap to produce and incredibly reliable, with less electronic "noise" than their modern cousins.

But their biggest drawback is inefficiency. A linear charger basically works by burning off excess energy as heat to keep the voltage steady. This means a huge chunk of electricity goes to waste, with efficiency often stuck between 30% and 60% . All that waste heat also means they have to be bulky, as they need large heat sinks to operate safely.

You will usually find linear chargers in low-power gear where cost and simplicity trump efficiency, like in small consumer electronics or basic battery maintainers for the workshop.

Switching-Mode Power Supplies (SMPS)

Switching-mode power supplies, or SMPS, represent a huge leap forward. Instead of burning off extra energy, an SMPS rapidly switches the power on and off thousands of times a second to regulate the voltage. This approach is far more efficient, hitting ratings of 85% to 95% or even higher.

Because they waste so little energy as heat, SMPS chargers can be much smaller, lighter and more powerful than linear models with a similar output. It is why they are the standard for almost all modern electronics, from your laptop’s power brick to the high-power units needed for electric vehicle charging.

For mobile applications, the advantages are crystal clear.

- Portability: Their compact and lightweight design is perfect for a mobile charging van.

- Efficiency: Less wasted electricity means lower running costs and more power delivered to your customer's vehicle.

- Power: They can handle the high-current demands of rapid EV charging without breaking a sweat.

The core idea behind an SMPS is efficiency through control. By intelligently switching the power flow, it slashes waste and boosts performance, making it the perfect choice for demanding jobs like on-the-go EV charging.

Smart Chargers: The Intelligent Approach

Smart chargers take the efficiency of SMPS technology and add a layer of digital intelligence. These devices can actually talk to the battery's management system (BMS). This two-way conversation lets the charger monitor things like temperature, voltage and state of charge in real-time.

Using this data, a smart charger constantly adjusts its output to deliver the safest, most efficient charge possible. It can ease off the current as the battery gets full or even shut down if it spots a problem, which dramatically extends the battery's lifespan and prevents damage. While frequent high-power DC fast charging can wear a battery out faster, a smart system helps reduce that strain by optimising the whole process.

This intelligent control is non-negotiable for commercial EV charging. For anyone looking to build a business, high-quality, reliable equipment is everything. You can explore options like the ZAPME MAX 300 mobile charger , which integrates these advanced features to deliver safe and dependable power to customers. That level of control protects both the customer's vehicle and your investment.

To make sense of it all, here is a quick breakdown of how these technologies stack up against each other.

Comparison of AC to DC Charger Technologies

| Charger Type | Key Advantage | Main Disadvantage | Typical Efficiency | Common Applications |

|---|---|---|---|---|

| Linear | Simple design and low cost | Very inefficient and bulky | 30-60% | Small electronics, workshop tools |

| SMPS | Highly efficient and compact | More complex, can create noise | 85-95% | Laptops, phones, EV chargers |

| Smart | Optimises battery health | Higher initial cost | 85-95%+ | Modern EVs, commercial charging |

As you can see, while linear chargers have their place, the real action for any serious application is with SMPS and smart chargers. Their efficiency and intelligent control are what make modern, high-power charging possible.

The Growing UK Market for Battery Chargers

It is impossible to ignore the surging demand for the humble battery charger ac to dc across the UK. This is not just a gentle upward curve; it is a powerful shift driven by two unstoppable forces: the rapid switch to electric vehicles and our ever-growing reliance on personal electronic devices. Together, they are carving out a massive market opportunity.

This growth is supercharged by supportive government policies promoting green energy and a genuine change in how we all think about power. As people move away from fossil fuels, the need for efficient, accessible charging solutions has become more urgent than ever. The scale of this shift is creating the perfect environment for new, agile business models to thrive.

A Market Poised for Explosive Growth

The numbers really do speak for themselves. The UK's battery charger market is already a substantial sector but its future looks even more impressive. Projections show an industry worth around USD 840.88 Million is on track to hit USD 1281.08 Million by 2034 .

That is a steady annual growth rate of 4.30% , year on year. For anyone looking for a new venture, this data points to a lucrative opening, particularly in the mobile EV charging space where services can adapt quickly to meet people where they are.

The increasing market value is a direct reflection of the UK's electric revolution. Every new EV on the road and every smart device in a pocket represents another customer in need of reliable charging, making it a prime sector for investment and innovation.

The Mobile Charging Advantage

While the whole charger market is growing, the mobile EV charging sector offers some unique and compelling advantages. Fixed charging stations require a huge upfront investment in land and infrastructure. A mobile service, on the other hand, is agile with far lower overheads.

An operator can go directly to where the demand is, whether that is a busy city centre, a remote festival or a stranded motorist on the side of the M1. This flexibility unlocks a premium service model—you are not just selling electricity; you are selling convenience and peace of mind. For a driver with a flat battery, an on-demand charging service is a lifeline worth paying extra for.

Calculating the Potential Earnings

So, how much can a mobile charging operator realistically make? The income streams are varied and can quickly add up to a healthy figure.

- Call-Out Fees: A standard fee just for attending a stranded driver can range from £30 to £50 .

- Per-kWh Pricing: Mobile operators can set a premium rate, often between 70p and 90p per kWh , which is higher than most fixed points.

- Subscription Services: Offering contracts to local businesses or fleet operators provides a reliable, recurring monthly income.

Let's break it down with a simple scenario. A single roadside rescue where you provide 15kWh of charge could earn you between £40 and £65 (call-out fee plus the energy). With just three or four similar jobs a day, a mobile operator could be looking at a daily revenue of £120 to £260 .

This business model transforms the technical process of AC-to-DC conversion into a profitable and scalable service, meeting a clear and growing need right here in the UK.

The Profitable Mobile EV Charging Business

Moving away from the technical specs of a battery charger ac to dc , let's look at where the rubber really meets the road: turning this technology into a profitable business. The mobile EV charging sector is not just a niche idea; it is a seriously practical venture that taps directly into the UK’s massive shift towards electric transport. For a smart operator, this is how you turn a technical service into a healthy income.

At its heart, the business is all about convenience. Fixed charging stations make drivers come to them. A mobile service completely flips that script by taking the power directly to the customer. This simple but powerful change creates a premium service that solves some of the biggest headaches for EV drivers, like range anxiety or finding yourself in a charging dead zone.

Breaking Down the Revenue Streams

A mobile EV charging business does not just rely on one source of income. It pulls from several, each adding to a strong bottom line. This multi-pronged approach means you are not dependent on a single type of customer, creating a resilient operation that can easily scale up. By blending these income streams, an operator can really maximise their daily earnings.

Here are the most common ways to make money:

- Emergency Call-Out Fees: This is the bread and butter for many mobile operators. When a driver is stranded with a dead battery, you charge a flat fee just for showing up. This is typically between £30 and £50 and that is before you have sold a single kilowatt of electricity.

- Per-kWh Pricing: On top of the call-out fee, you charge for the energy you deliver. Because you are offering immediate, on-the-spot convenience, you can command a premium rate, often between 70p and 90p per kilowatt-hour (kWh) .

- Subscription Services for Fleets: Think about local businesses with electric vans or company cars. They need reliable charging to keep their operations running. Offering a monthly subscription for scheduled top-ups gives you a predictable, recurring income that keeps cash flow steady.

- Event-Based Charging: Festivals, outdoor markets and corporate events are often held in places with terrible charging infrastructure. Setting up as a temporary charging provider for the day can be an incredibly lucrative, high-volume opportunity.

The real value here is not just selling electricity; it is selling a solution. Whether you are rescuing a stranded motorist or making sure a business fleet is ready for the morning rush, a mobile charging service provides immense value that people are more than happy to pay for.

This model is especially powerful when you look at the UK market's direction. The United Kingdom Electric Vehicle Charging Equipment Market is seeing incredible growth, expanding from around 50.64 thousand units to an expected 169.15 thousand units by 2030 . That is a compound annual growth rate of 21.32% , driven by government incentives and soaring demand. You can find out more about the UK's EV charging equipment market growth.

Calculating Your Potential Earnings

To get a feel for the real-world profitability, let's walk through what a typical day might look like for a single operator. The numbers add up quickly and show just how lucrative this can be, even on a small scale. And remember, a solid mobile AC to DC charger is the key piece of kit that makes all this possible.

Let's imagine a simple day focused on roadside assistance:

- Morning Call (8 AM): A driver runs out of charge on their commute. You charge a £40 call-out fee and provide 15kWh of energy at 80p/kWh (£12). Total earnings: £52 .

- Lunchtime Top-Up (1 PM): A local delivery van needs a quick boost to finish its route. This is a pre-arranged job that earns you £35 .

- Afternoon Rescue (5 PM): Another stranded motorist needs help. You charge a £50 call-out fee (for peak time) and deliver 20kWh of charge (£16). Total earnings: £66 .

In this pretty conservative scenario, your daily revenue would be £153 . If you work five days a week, that is over £765 per week or more than £3,000 per month from just a handful of calls a day.

The Advantages of Going Mobile

The mobile charging model has some clear wins over investing in fixed charging stations, which makes it a much more accessible way to get into the EV market. The initial outlay is lower and the operational flexibility is worlds apart.

Key Benefits of a Mobile Service:

| Advantage | Description |

|---|---|

| Lower Overheads | There is no need to buy or lease land and you can forget about costly grid connection fees. Your main asset is your vehicle and the charger inside it. |

| Ultimate Flexibility | You can go wherever the demand is highest—from busy city centres during the day to residential streets in the evening. |

| Premium Pricing | The on-demand nature of your service justifies higher prices. You are solving an immediate and urgent problem for your customers. |

| Scalability | It is straightforward to start with one van. As demand grows, you can simply add more vehicles to your fleet to cover a larger area. |

At the end of the day, a mobile EV charging business is a direct answer to the needs of a modern transport system. It takes the technical function of a battery charger ac to dc and wraps it in a service-based model that offers a fantastic return on investment. For any aspiring entrepreneur, it is a chance to get into a booming industry with a business plan that is proven, profitable and ready to grow.

Selecting and Maintaining Your Charging Equipment

Choosing the right battery charger ac to dc is probably the single most important investment you will make when setting up a mobile charging business. This bit of kit is the absolute heart of your operation, so putting durability, reliability and safety first will save you a world of pain and expense down the line. It is not just about raw power; it is about picking a unit that is genuinely built to survive the rigours of daily, on-the-road use.

When you are weighing up different models, a few key specs should be right at the top of your list. Make sure the output voltage and current are clearly stated, as you will need something compatible with a wide range of vehicles. Efficiency ratings are also a big deal—a more efficient charger means less wasted electricity and lower running costs for you.

Key Specifications for Mobile Chargers

For a mobile business, some features just are not negotiable. Portability is a given, of course, but you also need a unit that is tough enough to handle the unpredictable British weather.

- Weather Resistance: Look for an IP (Ingress Protection) rating. This number tells you how well the unit is sealed against dust and water, which is essential for operating safely outdoors, come rain or shine.

- Durability: Your charger has to be robust enough to cope with constant vibrations and bumps during transit. A solid casing and securely mounted internal parts are vital.

- Safety Certifications: Never, ever buy a charger that does not carry a CE mark. This is your guarantee that the product meets UK standards for health, safety and environmental protection.

- Connector Types: To reach the widest possible customer base, make sure your charger is fitted with the standard connectors used by EVs in the UK, like Type 2 and CCS .

Safety is paramount in this business. Beyond the unit itself, it is worth brushing up on essential battery safety practices.

Simple Maintenance for Longevity

Once you have got your equipment, a simple maintenance routine will protect your investment and keep it running safely for years to come. A few regular checks can head off expensive failures and stop your business from grinding to a halt.

A well-maintained charger is a reliable one. Spending just ten minutes on a weekly inspection can prevent a breakdown that costs you a full day's earnings and damages your reputation with customers.

Put together a simple checklist to follow:

- Inspect Cables: Check all your charging cables for any signs of fraying, cracking or general wear and tear. A damaged cable is a serious safety hazard and needs replacing immediately.

- Clean Connectors: Make sure every connector is clean and free from dirt or moisture. Any debris can cause a poor connection, leading to slow charging or, even worse, overheating.

- Check Cooling Fans: The vents for the cooling fans must be clear and unobstructed. Overheating is one of the main reasons chargers fail, so good airflow is absolutely essential.

Your Questions Answered

Here are a few of the most common questions we get about AC-to-DC battery chargers and the practical side of running a mobile EV charging business.

Can I Use Any AC to DC Charger for Any Battery?

Definitely not. It is vital to match the charger's output with the battery's specific needs. Getting this wrong can seriously damage the battery, shorten its lifespan or even create a safety hazard.

Always stick to the manufacturer's guidelines. While smart chargers offer more wiggle room by adapting their output, you still have to ensure they are compatible with the battery chemistry, whether it is Lithium-ion, Lead-Acid or something else.

How Much Can I Realistically Earn with a Mobile EV Charging Van?

Your earnings will naturally vary based on your location and how many hours you operate. A typical operator might set a £30-£50 call-out fee and then add a premium per-kWh rate of around 70p-90p .

Think about it this way: a single roadside rescue where you deliver 15kWh could net you anywhere from £40 to £65. If you manage just three or four of those calls a day, your daily revenue could easily be between £120 and £260 .

A great way to build a more stable, recurring income stream is by securing contracts with local business fleets. This supplements your on-demand call-outs and turns the technical function of a battery charger into a highly profitable mobile service.

What Are the Main Safety Precautions for a High-Power Charger?

Safety always, always comes first. You should only ever use chargers that are CE certified and built to UK standards and make sure the equipment is operated in a well-ventilated area to prevent overheating.

Get into the habit of regularly inspecting all your cables for damage—never use a frayed or faulty charger. And if you are starting a mobile charging business, it is crucial to have a qualified professional handle all the electrical installations. This ensures you meet commercial safety regulations and protects your investment.

Ready to power the future of driving with a reliable and profitable mobile charging solution? ZAPME offers cutting-edge mobile EV charging units, designed and built right here in the UK, to help you launch and grow your business. Explore our range of chargers at https://www.zapme.biz.