Guide to fleet ev charging: Optimise Your Fleet Operations

When you hear 'fleet EV charging' you probably picture rows of wall-mounted chargers at a depot. That's part of the story but it's not the whole picture. Fleet charging is really about creating a dedicated system to get your company's electric vehicles juiced up and ready for the day's work. This could mean installing fixed chargers but it also includes newer, more flexible mobile charging solutions that bring the power right to your vehicles, wherever they happen to be parked.

The Mobile Charging Revolution in Fleet Operations

Imagine charging your entire fleet without digging a single trench or waiting months for grid upgrades. This isn’t some far-off concept; it’s what’s possible today with mobile fleet ev charging . It represents a fundamental shift in logistics, ditching the old static, depot-focused model for a dynamic approach where power comes directly to the vehicles.

This method neatly sidesteps the biggest headaches of fleet electrification. Instead of facing huge upfront costs for hardware, civil works and substation upgrades, businesses can opt for a service-based model. It cuts out the long planning delays and the often-unpredictable timelines that come with getting the green light from local Distribution Network Operators (DNOs).

Unlocking Profit with Charging-as-a-Service

For companies looking to tap into the energy market, operating a mobile charger is a serious commercial opportunity. The model is refreshingly simple: you become the energy provider, delivering a vital service to other businesses that can't—or simply don't want to—install their own charging infrastructure.

This "Charging-as-a-Service" (CaaS) model opens up several revenue streams, making it a genuinely attractive venture. For your clients, the big win is convenience and avoiding massive capital outlay. For you, it's a direct route to profitability without being tied to a physical location. To get a better feel for how this stacks up against traditional setups, you can learn more about the future of EV charging with stationary vs mobile solutions.

Building Your Mobile Charging Business Case

Working out your potential earnings as a mobile charging operator is more straightforward than you might think. It really boils down to three things: understanding your costs, setting a competitive price and running an efficient operation. Let's break down how an operator can generate a substantial income.

The main ways you'll make money include:

- Per-kWh Pricing: This is the most common method. You charge a set rate for every kilowatt-hour of energy you deliver, which covers your electricity cost plus a healthy margin for your service.

- Fleet Subscription Models: For regular clients, you can offer monthly or annual subscriptions. These guarantee a certain number of charging sessions or a total amount of energy at a better rate, securing you consistent income.

- Service or Call-Out Fees: You can also apply a flat fee for each charging session, covering the time and logistics of getting the charger to the vehicle.

A mobile charging business thrives on flexibility. By not being tied to a fixed location, operators can go where the demand is highest—servicing delivery depots during the day, taxi ranks in the evening or even providing emergency top-ups for stranded vehicles.

A Practical Example of Calculating Earnings

Let’s run through a clear, step-by-step example to show the profit potential. We'll assume you're operating a mobile charger with a 75kW output.

Step 1: Work Out Your Costs

Your main operational cost is the electricity you use to fill your mobile battery unit. Let's say you've secured a good off-peak tariff at your own depot for £0.25 per kWh

.

Step 2: Set Your Price

You decide to offer your mobile charging service to local fleets at a competitive £0.50 per kWh

, plus a simple service fee of £10 per charging session

. This gives you a clear profit margin of £0.25 on every kWh you sell.

Step 3: Calculate Daily Operational Output

You plan to have your mobile charger out working for six productive hours each day, delivering power to various client vehicles.

- Charger Capacity: 75kW

- Operational Hours: 6 hours

- Total Energy Dispensed Daily: 75 kW x 6 hours = 450 kWh

Step 4: Determine Your Daily Profit

Now for the fun part. Let's calculate the potential daily earnings.

- Energy Profit: 450 kWh x £0.25 profit/kWh = £112.50

- Service Fee Profit: Assuming you service six different vehicles in that time, that’s 6 sessions x £10/session = £60.00

- Total Daily Gross Profit: £112.50 + £60.00 = £172.50

This simple calculation shows a potential gross profit of over £170 per day from a single mobile charging unit. Annually, this could translate into more than £44,000 in gross profit from just one vehicle operating five days a week.

By securing contracts with logistics hubs, last-mile delivery services or local councils, an operator can guarantee consistent demand and scale their operations by adding more units. This turns a logistical headache for other businesses into a profitable reality for you.

Understanding Your Fleet's True Charging Needs

Before you even think about charging hardware, you need to get a handle on your fleet's unique energy appetite. A successful switch to electric isn't built on guesswork; it's built on data. That’s why a deep dive into your operational demands is the essential first step, creating a data-driven foundation for a smart and cost-effective charging strategy.

This means looking way beyond just the number of vehicles you run. You have to dig into the nitty-gritty of their daily work lives to build an accurate picture of your total energy consumption.

Analysing Your Fleet's Daily Energy Use

To get started, you need to assess the core variables that dictate how much energy each vehicle actually needs. Think of it as creating a detailed energy profile for every van, car or lorry in your fleet.

Here are the key variables you need to be tracking:

- Vehicle Types: It sounds obvious but different EVs have different battery sizes and efficiency ratings. A large electric HGV will consume far more energy than a small electric van on the exact same route.

- Daily Mileage: How far does each vehicle travel per day? This is the single biggest factor in determining its daily energy requirement.

- Typical Dwell Times: How long are vehicles parked at the depot overnight or between shifts? This window defines your available charging time and dictates whether you can get by with slower chargers or need to invest in faster ones.

- Route Patterns: Are routes predictable and consistent or do they change every day? Hilly terrain or constant stop-start city driving will drain a battery much faster than steady motorway cruising.

To truly get to grips with your fleet's unique energy consumption patterns and optimise your charging schedules, using data analytics is a game-changer. For a deeper look at how this works, check out this article on Enhancing Logistics with Python Data Analytics.

From a Single Vehicle to the Entire Fleet

To keep things simple, start your calculation with just one vehicle. For instance, if a delivery van travels 100 miles a day and its efficiency is around 3 miles per kWh , it will need roughly 33 kWh of energy to replenish its battery each night.

Once you have this baseline, you can scale it up across the fleet. If you have 20 identical vans running similar routes, your fleet’s total daily energy need would be around 660 kWh (20 vans x 33 kWh). This simple multiplication gives you a powerful, concrete figure to work with.

This total energy demand is the cornerstone of your infrastructure plan. It tells you how many chargers you’ll need and what power output they should have to ensure every single vehicle is fully charged and ready for the next shift.

Think of your fleet's total power demand like the energy supply needed for a large office building. You wouldn't install the mains electrical system without first calculating the combined needs of all the lights, computers and air conditioning. The exact same principle applies to your fleet EV charging setup.

This careful planning helps you avoid two costly mistakes: under-investing, which leaves vehicles stranded and unable to work, and over-investing in expensive hardware that just sits there, unused.

However, it's clear the path to electrification varies wildly across the UK. A look at fleet electric vehicle adoption across UK cities reveals a sharp contrast in pace and infrastructure readiness. For example, Bristol leads the charge with 44.5% of its fleet now composed of EVs. Meanwhile, Transport for London (TfL) reported that only 3.2% of its heavy goods vehicles and vans are electric, highlighting the immense challenge posed by insufficient charging infrastructure. To understand these regional differences better, it's worth studying the divide in UK EV fleet adoption.

Fixed Depot vs. Mobile Charging Infrastructure

Choosing between fixed and mobile charging isn't just a technical decision for a fleet manager; it's a strategic one. This choice fundamentally shapes your budget, your day-to-day operational agility and how quickly you can get your electric fleet on the road. It’s not simply about picking a charger – it’s about designing the entire energy ecosystem that will power your business.

Most people are familiar with the traditional fixed depot model. You install permanent AC or DC charging points at your home base, which is a great fit for fleets with predictable, return-to-depot schedules. These systems are solid and reliable once they're up and running, giving you a dedicated power source for vehicles that can sit and charge overnight.

The problem is, getting to that point can be a minefield of challenges. The upfront cost for the hardware, civil engineering works and software can be eye-watering. Even more frustrating, many depots simply don’t have the grid capacity to support a fleet of EVs. This leads to lengthy and expensive applications for upgrades from Distribution Network Operators (DNOs), potentially stalling an entire electrification project for months, if not years.

The Strategic Edge of Mobile Fleet Charging

This is where mobile charging flips the script. Instead of bringing your vehicles to the power, you bring the power directly to your vehicles. Mobile charging units are essentially large, powerful batteries on wheels. They can be rolled out rapidly wherever you need them, completely sidestepping grid connection delays and the headache of digging up your depot.

This approach offers incredible flexibility. A mobile charger can service vehicles at your main depot, a secondary site, a client’s location or even provide a lifeline with emergency roadside assistance. For fleets with dynamic routes or those operating from multiple, rented or temporary sites, this agility is a genuine game-changer. Installing permanent kit just isn't an option in those scenarios.

What's more, mobile charging scales with you. A fleet can start small with one or two mobile units and simply add more as the number of EVs grows. This ‘pay-as-you-grow’ model means you avoid the risk of sinking a huge investment into fixed infrastructure that might be overkill today or insufficient tomorrow.

Fixed Depot Charging vs. Mobile Charging: A Head-to-Head Comparison

To really weigh up the options, it helps to see a direct comparison of the two models across the factors that matter most to fleet operators. The table below breaks down the key differences in cost, deployment speed and operational flexibility.

| Factor | Fixed Depot Charging | Mobile Charging |

|---|---|---|

| Upfront Cost | High (hardware, installation, grid upgrades) | Low to Medium (vehicle, charger unit) |

| Deployment Speed | Slow (months to over a year) | Fast (days to weeks) |

| Grid Dependency | Entirely dependent on grid capacity | Independent of the grid at the point of use |

| Scalability | Difficult and expensive to scale | Easy and cost-effective to scale up or down |

| Flexibility | Low (fixed location, inflexible) | High (can serve multiple sites) |

| Operational Risk | High (grid outages can halt all charging) | Low (can be recharged from various sources) |

Ultimately, this side-by-side view shows how each approach fits different operational and financial strategies, helping you decide which path makes the most sense for your fleet's unique needs.

The real power of mobile charging is its ability to de-risk the transition to electric. It transforms a massive capital expenditure project into a far more manageable and flexible operational expense, allowing fleets to electrify faster and with much greater confidence.

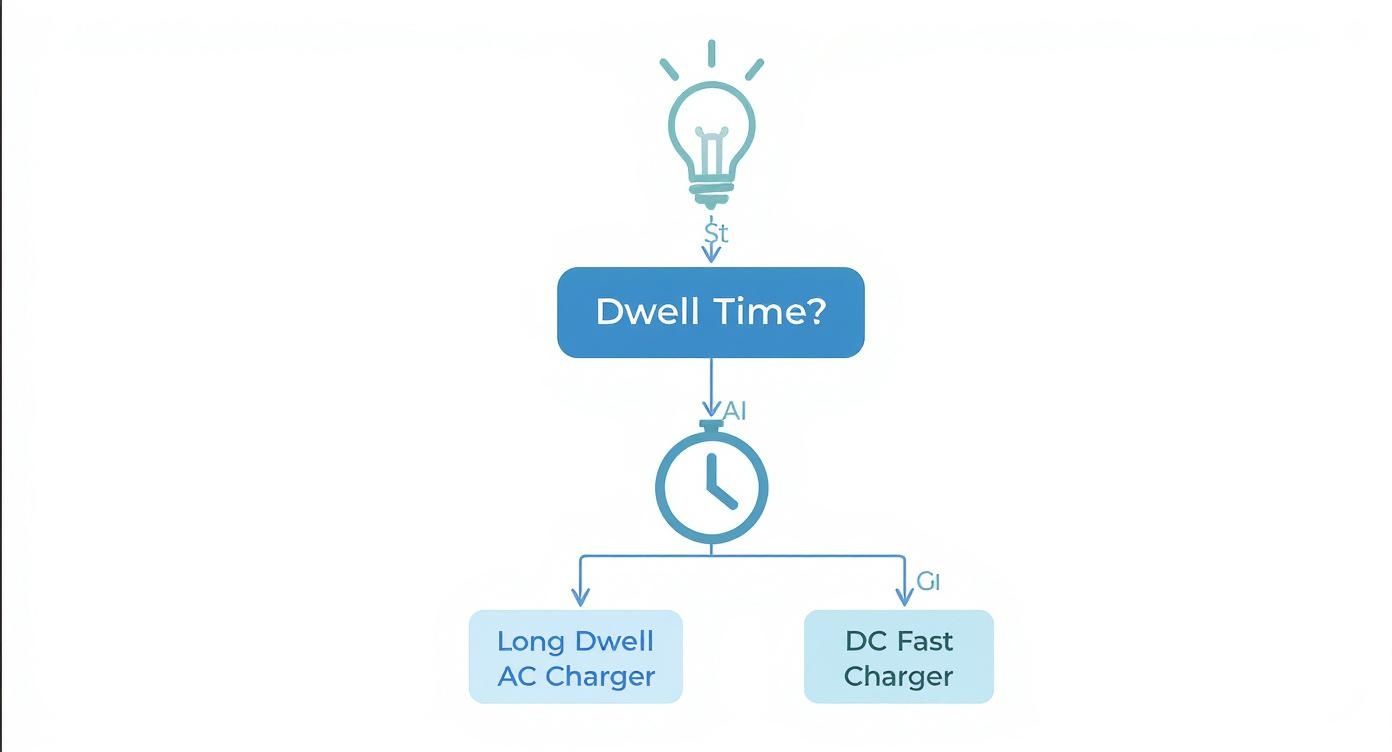

This decision tree gives a clear visual of how a fleet’s daily patterns, especially vehicle dwell time, should guide the choice of charging infrastructure.

As the chart shows, fleets with long, predictable overnight stops are a natural fit for AC chargers. In contrast, those needing rapid turnarounds will benefit more from DC solutions—a role that both fixed and mobile rapid chargers can fill. You can explore the different hardware options in more detail in our guide to commercial EV charging solutions in the UK.

For many fleets, the best solution isn't an either/or choice. It's a hybrid approach that combines the steady reliability of fixed chargers for overnight stays with the go-anywhere flexibility of mobile units for daytime top-ups and off-site support.

Navigating Costs and Funding Your EV Transition

Making the switch to an electric fleet is a serious financial commitment but it doesn't have to be a painful one. The key is to look past the sticker price of the vehicles and get a handle on the complete financial picture. Unpacking the total cost of ownership (TCO) is your first step towards building a charging setup that’s both effective and affordable.

This means you need to break down every single expense, from the upfront cost of hardware and installation to the ongoing bills for energy and maintenance. Only when you have this kind of financial clarity can you put together a strategy that will pay off in the long run.

Understanding the Total Cost of Ownership

The real cost of fleet EV charging goes way beyond the price of the chargers themselves. To build a realistic budget, you need to account for several connected expenses that all add up to your TCO.

- Hardware Costs: This is the obvious one – the price of the charging units. This could be anything from slower AC models for overnight top-ups to powerful DC rapid chargers needed for quick turnarounds.

- Installation and Civil Works: Getting a depot ready can get expensive. Think trenching for cables, concrete pads and mounting hardware. For fixed infrastructure, this can easily be one of the biggest initial costs.

- Grid Connection Upgrades: Many commercial sites simply don't have enough power for a fleet of EVs. Upgrading your grid connection can be a slow, bureaucratic and very costly process.

- Energy Costs: This is your new fuel bill. It’s hugely influenced by your electricity tariff and whether you can be smart about scheduling charging during cheaper, off-peak hours.

- Maintenance and Software: Just like any other critical equipment, chargers need regular servicing to stay reliable. On top of that, you'll likely have software subscriptions for managing smart charging, payments and reporting.

Embracing Flexible Funding Models

The huge upfront capital needed for traditional depot charging is a major roadblock for many businesses. Thankfully, new funding models are popping up that make the transition much more manageable by turning a massive one-off investment into a predictable monthly cost.

Charging-as-a-Service (CaaS) is a game-changer here. It bundles hardware, software, installation and maintenance into a single subscription fee. This lets you electrify your fleet without draining your capital, freeing up cash for other parts of the business.

This approach takes a lot of the risk out of the investment and gives you much-needed flexibility. As your fleet expands, a CaaS agreement can scale right alongside you, ensuring your charging capacity always keeps up without you having to find another huge chunk of cash. For a deeper dive into the different ways to pay for your setup, check out our guide on finance for EV chargers .

Tapping into Government Grants and Incentives

The UK government is keen to see businesses switch to electric and offers various grants to soften the financial blow. Taking full advantage of these schemes can seriously reduce your overall TCO.

A great example is the Workplace Charging Scheme (WCS) . It’s a voucher-based system that helps with the upfront costs of buying and installing charge points. It offers up to £350 per socket for as many as 40 sockets across all of a company's sites.

This support is part of a bigger national push to build out the UK's charging infrastructure. The public network has grown massively in recent years. By October 2025, there were more than 1.7 million battery electric vehicles on UK roads, supported by 86,798 public charge points—that's a staggering 426% increase since January 2020. With a national target of 300,000 public chargers by 2030, it’s clear the government is committed to backing the EV transition.

Implementing and Managing Charging Operations

Moving from a plan on paper to a fully operational charging system is where the real work begins. This isn't just about installing hardware; it's about building an intelligent, efficient ecosystem to power your entire fleet and keep it on the road.

Getting the details right at this stage is crucial. A successful implementation covers everything from the initial site survey to the final flick of the switch, ensuring your charging operation isn't just functional but genuinely productive and cost-effective.

From Blueprint to Reality: A Step-by-Step Project Plan

A successful fleet EV charging project needs a clear, structured plan. Each stage builds on the last, guiding you from concept to a smooth rollout.

Here's a simple roadmap to follow:

- Site Assessment and Feasibility: First things first, get qualified electrical engineers to survey your depot. They'll assess your grid capacity, pinpoint the best spots for chargers and flag any potential hurdles like trenching needs or substation upgrades.

- Hardware Procurement and Partner Selection: Next, choose your charging hardware and management software. Look for partners with proven experience in commercial fleet installations and a reputation for solid, reliable support.

- Installation and Civil Works: This is the hands-on part. It involves everything from laying conduits and pouring concrete bases to installing the charging units and connecting them to your power supply.

- Commissioning and Testing: Once installed, every single charger needs to be rigorously tested. This final check ensures each unit talks to the management software correctly and delivers power safely before your vehicles ever plug in.

The Power of Smart Charging Software

Simply plugging in every vehicle as it returns to the depot is a recipe for eye-watering energy bills. Modern charging operations depend on smart charging software to orchestrate the whole process, turning a logistical headache into a major cost-saving advantage. Think of this software as the brain of your entire charging ecosystem.

A Charge Point Management System (CPMS) is your key to minimising electricity costs. It lets you schedule charging for cheaper off-peak hours, automatically powering up vehicles overnight when tariffs are at their lowest. It also handles load balancing, making sure you never exceed your site’s power limit and avoiding those punishing demand charges from your energy supplier.

A well-managed charging operation doesn't just replenish batteries; it actively optimises energy consumption. Smart software ensures every vehicle is ready for its next shift at the lowest possible cost, directly boosting your bottom line.

Future-Proofing with Vehicle-to-Grid Technology

Looking ahead, new technologies like Vehicle-to-Grid (V2G) are set to turn charging from a cost centre into a potential revenue stream. V2G allows energy to flow both ways, meaning your parked EV fleet can not only draw power but also sell surplus energy back to the grid during peak demand.

Imagine your fleet acting as one giant battery, helping to stabilise the local grid while earning you money. Although it's still an emerging technology, V2G presents a compelling financial case for fleet operators, turning idle vehicle batteries into active, profitable assets. It's quickly becoming a key consideration for future-proofing any major investment in fleet EV charging infrastructure.

The growth of high-speed public infrastructure supports this wider ecosystem. By June 2025, the UK had 82,369 public EV charging devices across over 40,479 locations, marking a 35% increase from the previous year. Crucially for fleets, ultra-rapid chargers saw a 58% rise, with 8,619 units now capable of delivering 150 kW or more, showcasing the nation's commitment to high-speed charging. You can learn more about the UK's charging expansion and what it means for fleets.

Common Questions About Fleet EV Charging

As you map out your fleet's move to electric, the big, practical questions naturally start to surface. It's a huge operational and financial shift, so it’s only right to have concerns about costs, logistics and the bottom line. Let's tackle some of the most common queries head-on to give you the clarity you need.

We'll get straight to the point on everything from the real-world earnings of a mobile charging setup to the practical headaches of installing fixed depot chargers. The aim here is to arm you with the insights to make confident, well-informed decisions for your fleet.

How Much Can I Realistically Earn Operating a Mobile EV Charger for Fleets?

This is often the first question and for good reason. Your potential earnings hinge on a few key things: the power of your charger, how many hours you operate it each day, your local electricity costs and the pricing you set for your clients. A smart strategy finds the sweet spot between competitive pricing and a healthy profit margin.

A simple, effective model is to add a margin to your electricity cost and tack on a service fee. Let's break it down with an example.

- Your Cost: Let's say it costs you 25p per kWh to charge your mobile unit.

- Your Price: You then offer your mobile charging service to local fleets at 45p per kWh .

- Your Profit Margin: That leaves you with a clean profit of 20p for every kWh you sell.

If you're running a 75kW mobile charger for six solid hours a day, you could deliver around 450 kWh of energy. That works out to a potential gross profit of £90 per day from the energy alone and that's before you add any service or call-out fees. Land a few regular contracts with local delivery firms or taxi companies and you've got consistent demand that turns your mobile charger into a serious business asset.

What is the Biggest Hurdle When Setting Up Fixed Depot Charging?

Without a doubt, the single biggest—and most frequently underestimated—hurdle is getting enough power from the grid. Most commercial depots simply weren't built to handle the enormous electrical load needed to run a bank of DC fast chargers at the same time. It’s the one issue that can stop an entire electrification project in its tracks.

Applying for a grid upgrade from your local Distribution Network Operator (DNO) is often a long, drawn-out and frustrating ordeal. The timeline can easily stretch from several months to well over a year, throwing a massive spanner in your project plans.

The costs for a grid upgrade can also be eye-watering, sometimes running into hundreds of thousands of pounds for new substations or major cabling work. This 'grid constraint' is precisely why so many fleets are now exploring more flexible and grid-independent solutions like mobile charging first.

Is Special Software Essential for Managing Fleet EV Charging?

Technically, you could juggle a couple of EVs without it. But trying to run a professional fleet that way would be incredibly inefficient and, ultimately, very expensive. A smart Charge Point Management System (CPMS) isn't just a 'nice-to-have'—it's the central nervous system for an optimised, cost-effective operation.

Think of this software as the brain of your charging ecosystem. It lets you:

- Monitor chargers in real-time to check they’re working and fix faults fast.

- Schedule charging sessions to automatically take advantage of cheaper off-peak electricity.

- Manage the electrical load intelligently to stop you from exceeding your depot's power limit and getting hit with huge penalty charges.

- Track energy use for each vehicle for spot-on reporting and cost allocation.

Investing in a good CPMS is fundamental to lowering your total cost of ownership and getting the most out of your fleet EV charging setup.

Can I Mix Different Charger Types in My Fleet Depot?

Yes, absolutely. In fact, for many fleets, a mixed-charging strategy is the most practical and cost-effective way to go. Combining different charger types lets you match the power delivery to the specific needs of your vehicles and their schedules. It’s all about getting maximum flexibility while keeping a lid on infrastructure costs.

For example, you can install slower, cheaper AC chargers (usually 7-22kW ) for vehicles that sit idle for long periods, like those parked up overnight. This approach is also a bit gentler on the vehicle's battery health in the long run.

Then, for vehicles that need a quick turnaround or a fast top-up between shifts, one or two powerful DC fast chargers ( 50kW and up) are the perfect fit. A smart charging management system can orchestrate this whole setup, prioritising vehicles based on their battery level and their next job, all while making sure you never pull too much power from the grid.

Ready to overcome grid constraints and simplify your fleet's transition to electric? ZAPME offers innovative mobile EV charging solutions that bring the power directly to you. Explore our flexible and scalable options at https://www.zapme.biz.